In the world of product packaging, the inner tray, though seemingly insignificant, is the most important part of the box. Imagine, an expensive goods, after careful design and production, but in the transportation process because of packaging problems and damage to the inner tray. Not only will cause economic losses, serious may make the brand's reputation decline, the brand trust accumulated over the years at once destroyed. According to relevant data shows that in the logistics loss, 70% of the internal tray design is not reasonable. This can not help but let a person ask, exactly how to choose through the inner tray, effectively reduce the risk of transportation? Next let us explore together.

The Four Core Dimensions of Packaging Box Insert Selection

1. Material Performance Test

Comparison of commonly used materials: EVA, sponge, corrugated paper, these three materials are more common in the box liner, EVA material, strong pressure resistance, can effectively buffer the external impact, in terms of shock resistance, excellent performance, but the cost is relatively high. The sponge is soft, has a certain buffering effect, the cost is moderate. Corrugated cardboard cost is lower, but the compression and shock resistance is relatively weak. The actual data show that after the compression test, EVA is the least deformed when subjected to 50kg of pressure, followed by sponge, and the deformation of corrugated paper is more obvious. In the seismic test, EVA can more effectively absorb the energy brought about by vibration. In terms of cost, for the same volume of inner tray, the cost of corrugated paper is the lowest, sponge is moderate, and EVA is the highest.

Environmental Trend: With the concept of environmental protection gradually taking root in people's hearts, biodegradable EPE materials have been more widely used in high-end brands. For example, an internationally renowned high-end skincare brand uses biodegradable EPE material as the inner tray of the product box, which not only meets the requirements of environmental protection, but also shows the social responsibility that the brand should bear, and then enhances the brand image.

2. Structure Adaptation Logic

Solution for irregularly shaped products: For irregularly shaped products, 3D scanning and then modeling of the customized inner tray becomes the best choice. Through scanning, the outline of the product can be accurately obtained, and then use the modeling technology to design a perfectly adapted inner tray structure, in this way, it can ensure that the product is stable and does not shake during the transportation process.

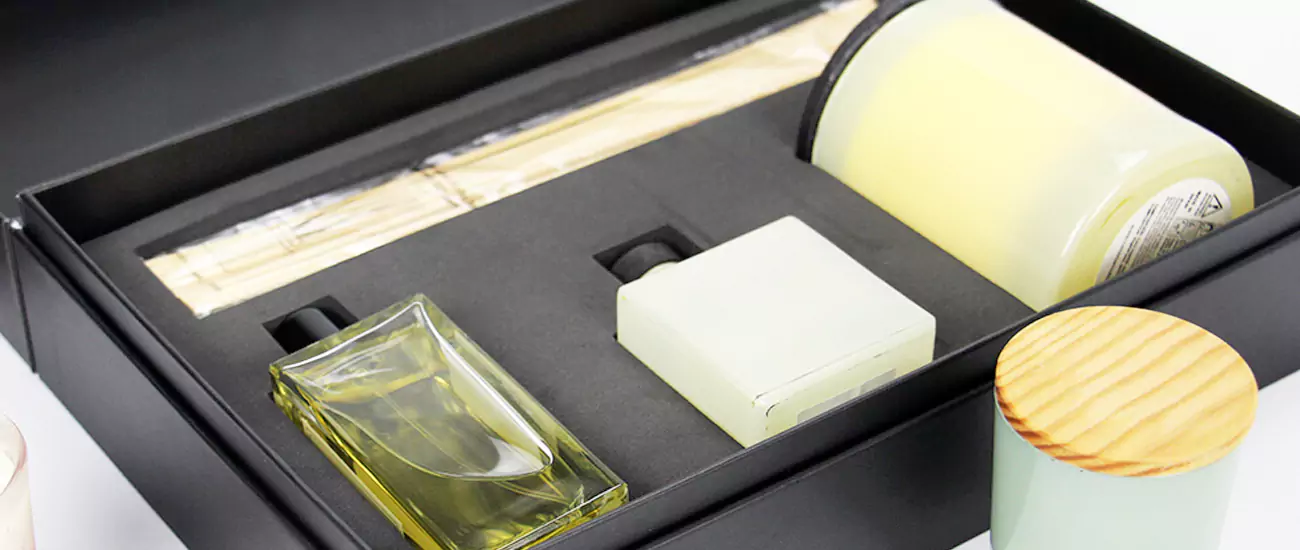

Layered design skills: In cosmetic set packaging, layered design can skillfully enhance the sense of opening ceremony. For example, the different categories of cosmetics are placed in layers in the inner tray, when consumers open the box, the products will be displayed in front of the eyes in turn, as if starting a surprise journey, thus greatly enhancing the added value of the product.

3. Cost Control

Different starting quantities can have a significant impact on the unit price of the inner tray. Usually, the higher the quantity, the lower the unit price. Enterprises need to make accurate calculations according to their own production plans and market conditions to customize boxes and control costs effectively.

Hidden cost warning: do not buy poor quality inner tray to save cost, which will bring the cost of after-sales claims, but also leave a bad impression on consumers. There is an electronic product enterprise, in order to save costs and choose poor quality inner tray, the result in the transportation process, a large number of products because of the inner tray protection is not strong enough and damaged, and ultimately bear a high amount of after-sales claim costs, this cost is far more than the cost of saving the inner tray.

4. Value-added Brand Design

Molding accuracy standard: For luxury packaging, the molding accuracy of the inner tray is extremely high. For example, for a famous luxury brand, the molding error of its packaging inner tray should be controlled within 0.1mm, because the high precision molding process can make the inner tray fit perfectly with the product, thus highlighting the high-end quality of the brand.

Co-branded packaging: the foil stamping process on the surface of the inner tray can significantly increase the unit price. For example, a brand and a well-known artist co-launched products, through the use of hot stamping technology on the surface of the inner tray to print out the co-branded elements, so that the product is more unique and collectible value, the customer unit price has also increased by 30%.

Choosing the right inner tray is crucial for product packaging, which not only concerns the safe transportation of the product, but also affects the image of the brand and the economic benefits of the enterprise.

Crown Win Packaging Factory has 17 years of experience in customized packaging boxes and has served 10,000+ large and small enterprises around the world, which is worthy of your trust. We provide free structural design services to help you create unique product packaging boxes. Redefine the value of your products with customized packaging and start a new journey of packaging.

Crown Win

Crown Win Advantages of Ordering Custom Paper Boxes in Bulk from a Supplier

Advantages of Ordering Custom Paper Boxes in Bulk from a Supplier