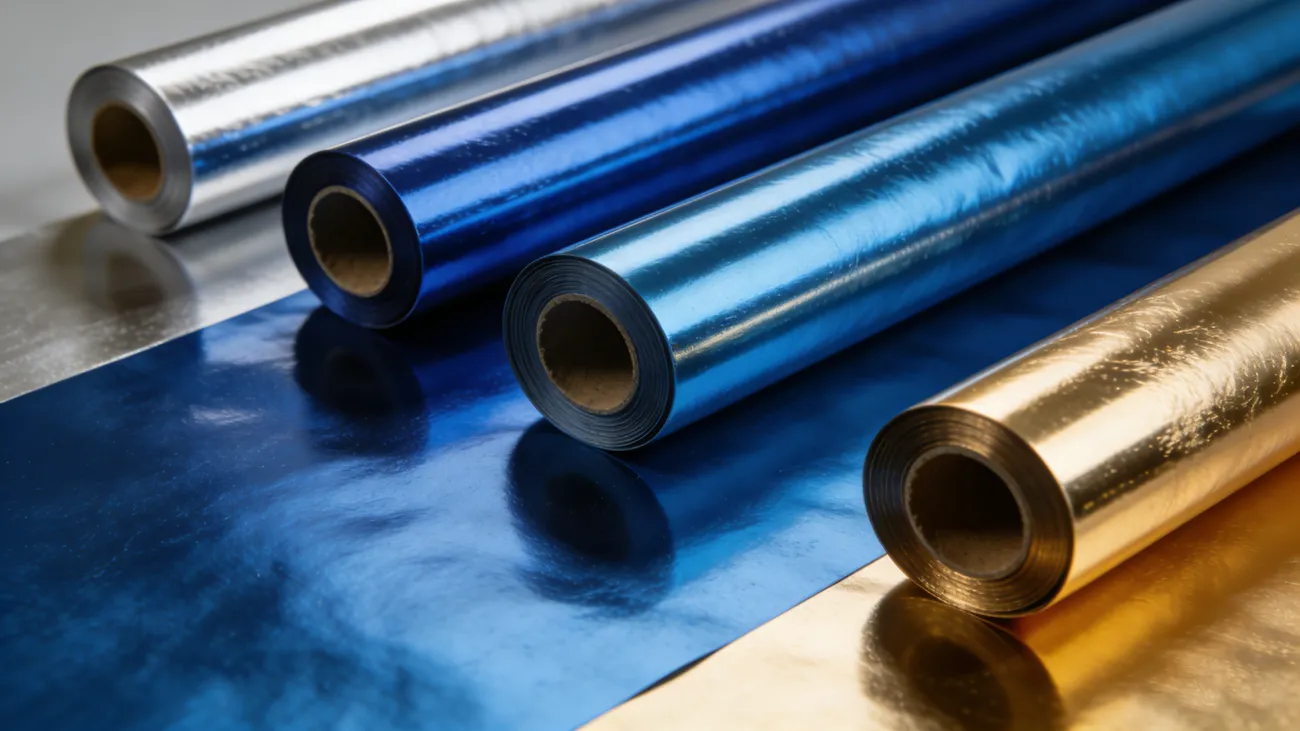

Hot stamping (hot stamping) is a widely used decorative technique in industries such as packaging and printing, but oxidation has always been a problem that troubles industry professionals. Once hot stamping oxidation occurs, it not only damages the appearance of the product, but also causes many almost irreparable huge economic losses. Crown Win deeply understands these troubles. Next, let us introduce the causes, cases, and practical solutions of oxidation problems.

Common cases of hot stamping oxidation

In actual production, hot stamping oxidation often occurs in specific scenarios. The following are typical cases:

Printing+hot stamping+laminating process: Printing and hot stamping followed by laminating can easily lead to extensive oxidation. For example, after printing with blue or bright silver hot stamping paper, the ink reacts with the hot stamping paper, causing oxidation. Even after black ink printing and hot stamping, it is impossible to avoid oxidation of the hot stamping paper.

Hot stamping on black cards: Directly stamping on black cards or embossed black cards is prone to complete oxidation. Black cards contain special ingredients that can easily react with the aluminum layer of the hot stamping paper, leading to serious oxidation problems.

Pearlescent paper hot stamping: Pearlescent paper has a special surface material, and after hot stamping, spots often appear at the hot stamping position, which is a typical oxidation phenomenon.

Touch paper/touch film hot stamping: When hot stamping on touch paper or touch film, if the process details are accidentally ignored, it can also cause oxidation, affecting the tactile and visual effects of the product.

Other situations: For example, the area of the rope imprint on the hot stamping product is prone to oxidation reaction with the hot stamping paper, which is often overlooked in production.

The core reason for hot stamping oxidation

The occurrence of hot stamping oxidation is not accidental, it requires specific conditions and is mainly caused by the following factors:

Moisture factor: Moisture is one of the key factors that trigger oxidation. If the glue used in the laminating process is not completely dry, moisture will seep into the paper and react with the aluminum layer in the hot stamping paper, leading to oxidation. In addition, insufficient drying time after applying oil on the surface of printed materials, or hot stamping before the printing ink is completely dried, can also cause moisture to react with the aluminum layer, leading to oxidation.

Base material composition: Base materials containing carbon black (such as various inks) or acidic and alkaline components (such as black cardboard and pearlescent paper) will react directly with the aluminum layer of the hot stamping paper during the direct hot stamping process, inevitably leading to oxidation.

Unreasonable production processes: Many process steps may lead to oxidation. For example, hot stamping directly on ink without adding an isolation layer.

Practical solution for hot stamping oxidation

1. Solve the problem of moisture

Keep the material storage environment dry, strengthen humidity monitoring of raw materials and processing, prevent moisture from affecting the hot stamping paper. If moisture is unavoidable, anti-seepage treatment should be carried out.

Control the drying time of the glue to avoid residual moisture.

Choosing antioxidant series hot stamping paper can fundamentally reduce the possibility of oxidation.

2. Solutions for solutions containing carbon black and acidic/alkaline components

Avoid direct hot stamping on the surface of black cardboard and pearlescent paper to reduce direct contact between reactive components and the hot stamping paper.

Use isolation methods (such as oil coating or bonding) to separate the substrate or printing surface from the hot stamping paper, blocking the reaction pathway.

On the basis of isolation treatment, further use antioxidant series hot stamping paper to double prevent oxidation.

3. Production process optimization

Select matching hot stamping paper based on different products to improve material compatibility and reduce reaction risks.

When designing production processes, avoid directly hot stamping hot stamping paper on ink, and try to avoid processes such as laminating, UV lamp treatment, UV oil coating, etc. after hot stamping.

Popularize knowledge of hot stamping oxidation technology in departments such as procurement, process, technology, and production, raise awareness of prevention, ensure mutual reminders in each link, and form a full chain risk control.

Hot stamping oxidation is not an unsolvable problem. As long as we accurately identify the cause of oxidation, choose suitable materials (such as antioxidant hot stamping paper), and optimize production processes, we can effectively avoid oxidation risks and ensure the quality of hot stamping products.

Crown Win

Crown Win Elevate Your Brand: How Creative Double-Door Packaging Can Revolutionize the Hair Curling Iron Market

Elevate Your Brand: How Creative Double-Door Packaging Can Revolutionize the Hair Curling Iron Market